| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HUA XIANG CUN |

| Price : | $10,000.00 - $80,000.00/sets |

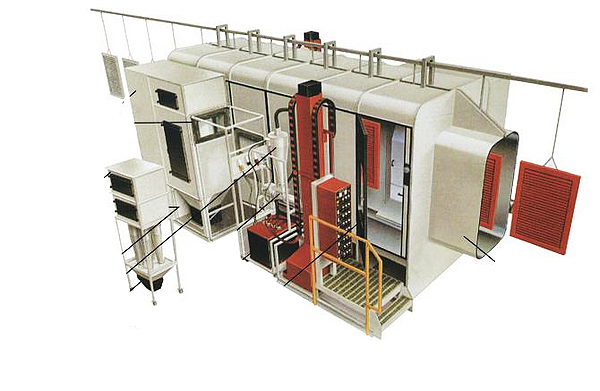

A static powder coating production line is a system designed for the efficient application of powder coatings to various substrates. Here are some key aspects of a static powder coating production line:

Components

Pre-Treatment Section:

Cleaning: The surface of the workpieces is cleaned to remove

contaminants (e.g., oils, dust) to ensure good adhesion of the

powder coating.

Phosphating: Often, a phosphating step is included to enhance

corrosion resistance.

Powder Coating Booth:

Static Powder Spray Gun: Utilizes electrostatic principles to

charge the powder particles, allowing them to adhere to the

grounded workpieces.

Ventilation System: Maintains air quality by filtering overspray

and providing a safe working environment.

Curing Oven:

Heat Application: The coated workpieces are moved into a curing

oven where the powder melts and chemically reacts to form a

durable, solid finish.

Temperature Control: Precise temperature control is essential for

achieving optimal curing results.

Cooling Zone:

Cooling: After curing, the workpieces are cooled down to room

temperature before further handling or packaging.

Quality Control:

Inspection: Finished products are inspected for coating quality,

thickness, and adhesion to ensure they meet specifications.

Advantages

Efficiency: The system allows for high production rates, reducing

lead times.

Environmental Benefits: Powder coatings are typically free of

solvents and volatile organic compounds (VOCs), making them more

environmentally friendly.

Durability: Provides a tough, long-lasting finish that resists

chipping, scratching, and fading.

Applications

Automotive Parts: Used for coating various automotive components.

Home Appliances: Suitable for appliances like refrigerators, ovens,

and washing machines.

Industrial Equipment: Ideal for machinery and tools requiring

protective coatings.

Considerations

Training: Operators should be trained to ensure proper use of

equipment and safety protocols.

Maintenance: Regular maintenance of the production line is

essential for optimal performance and longevity.

Material Compatibility: Ensure that the chosen powder coating is

suitable for the materials being coated.

A static powder coating production line is an effective solution

for achieving high-quality finishes in various industries.

item | value |

Type | Coating Production Line |

Substrate | Steel |

Condition | New |

Machine Type | powder coating line |

Video outgoing-inspection | Provided |

Machinery Test Report | Not Available |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | PLC, Engine, Pressure vessel |

Coating | Powder Coating |

Place of Origin | China |

Zhejiang | |

Brand Name | HUA XIANG CUN |

Voltage | 380V 50-60Hz |

Power | ODM |

Dimension(L*W*H) | ODM |

Warranty | 12 month |

Key Selling Points | Easy to Operate |

Applicable Industries | Manufacturing Plant, Retail, Printing Shops, Construction works |

Showroom Location | Egypt, Canada, Germany |

Weight (KG) | 10000 |

Machine Type | Spray Booths, Painting Equipment, Pre-treatment Equipment,

Conveying Equipment, Curing oven, Coating Equipment |

After-sales Service Provided | Engineers available to service machinery overseas |

Material | 1.2mm steel |

Insulation thickness | 120mm |

Insulation Material | Rockwool |

|