| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HUA XIANG CUN |

| Price : | $10,000.00 - $80,000.00/sets |

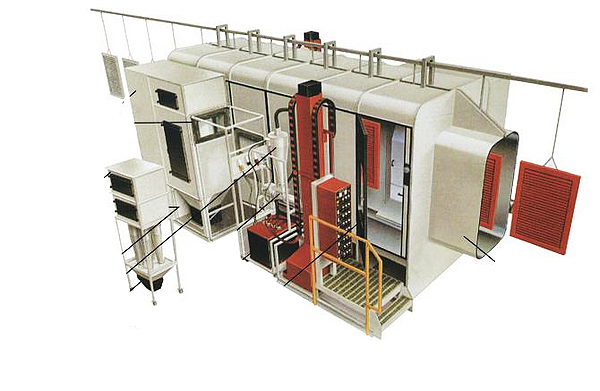

HXC electrostatic powder spray production line is an automated system specifically designed for coating workpieces. It typically includes the following key components:

Pre-Treatment Equipment:

Powder Spray Machine:

Powder Recovery System:

Curing Oven:

Cooling System:

Automated Conveyor System:

Control System:

Quality Inspection Equipment:

Post-Treatment Equipment (optional):

The electrostatic powder spray production line significantly improves production efficiency and ensures coating quality through efficient automation processes, making it widely applicable in industries such as automotive, home appliances, and machinery.

item | value |

Type | Coating Production Line |

Substrate | Steel |

Condition | New |

Machine Type | powder coating line |

Video outgoing-inspection | Provided |

Machinery Test Report | Not Available |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | PLC, Engine, Pressure vessel |

Coating | Powder Coating |

Place of Origin | China |

Zhejiang | |

Brand Name | HUA XIANG CUN |

Voltage | 380V 50-60Hz |

Power | ODM |

Dimension(L*W*H) | ODM |

Warranty | 12 month |

Key Selling Points | Easy to Operate |

Applicable Industries | Manufacturing Plant, Retail, Printing Shops, Construction works |

Showroom Location | Egypt, Canada, Germany |

Weight (KG) | 10000 |

Machine Type | Spray Booths, Painting Equipment, Pre-treatment Equipment,

Conveying Equipment, Curing oven, Coating Equipment |

After-sales Service Provided | Engineers available to service machinery overseas |

Material | 1.2mm steel |

Insulation thickness | 120mm |

Insulation Material | Rockwool |

|