| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HUA XIANG CUN |

| Price : | $10,000.00 - $80,000.00/sets |

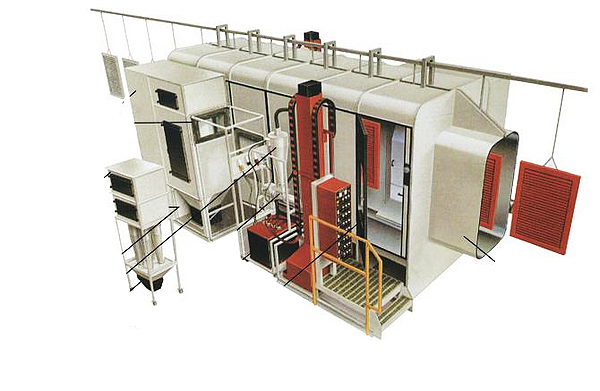

A static powder coating production line is a technology used for coating metal or other materials, offering advantages such as efficiency, environmental friendliness, and cost-effectiveness. Here are the main components and functions of a static powder coating production line:

1. Powder Supply System

Powder Storage Hopper: Stores coating powder to prevent moisture

and contamination.

Powder Delivery Device: Uniformly transports powder to the spray

gun, ensuring a consistent coating effect.

2. Coating Equipment

Electrostatic Spray Gun: Uses electrostatic principles to attract

powder to the workpiece surface, ensuring an even coating.

Spraying Chamber: Provides a closed space to reduce powder

dispersion and improve coating efficiency.

3. Heating and Curing Oven

Preheating Zone: Preheats the workpiece to enhance powder adhesion.

Curing Zone: Heats the powder to melt it and form a durable

coating, typically curing at 180-200°C.

4. Workpiece Conveying System

Conveyor Belt: Automates the transportation of workpieces,

increasing production efficiency.

Hanging System: Suspends workpieces to ensure uniform spraying.

5. Filtration and Recovery System

Powder Recovery Device: Collects unused powder to minimize waste

and lower costs.

Air Filtration System: Filters dust generated during spraying,

protecting worker health.

6. Control System

PLC Control System: Enables automated control, monitors the

production process, and ensures stability and consistency.

Human-Machine Interface: Allows operators to easily set and adjust

parameters.

Advantages

Environmentally Friendly: Solvent-free, reducing volatile organic

compounds (VOCs) emissions.

High Efficiency: Uniform coatings with strong adhesion, reducing

defect rates.

Cost-Effective: Reusable powder lowers material costs.

The static powder coating production line is widely used in

industries such as automotive, home appliances, furniture, and

construction, making it an essential part of modern coating

technology

item | value |

Type | Coating Production Line |

Substrate | Steel |

Condition | New |

Machine Type | powder coating line |

Video outgoing-inspection | Provided |

Machinery Test Report | Not Available |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | PLC, Engine, Pressure vessel |

Coating | Powder Coating |

Place of Origin | China |

Zhejiang | |

Brand Name | HUA XIANG CUN |

Voltage | 380V 50-60Hz |

Power | ODM |

Dimension(L*W*H) | ODM |

Warranty | 12 month |

Key Selling Points | Easy to Operate |

Applicable Industries | Manufacturing Plant, Retail, Printing Shops, Construction works |

Showroom Location | Egypt, Canada, Germany |

Weight (KG) | 10000 |

Machine Type | Spray Booths, Painting Equipment, Pre-treatment Equipment,

Conveying Equipment, Curing oven, Coating Equipment |

After-sales Service Provided | Engineers available to service machinery overseas |

Material | 1.2mm steel |

Insulation thickness | 120mm |

Insulation Material | Rockwool |

|